Description

The works consist of the execution of the AAVV and WWTP of the municipality of Iznatoraf (Jaén) which has a population of 1,250 inhabitants.

GROUPING OF SPILLS:

There are 6 discharge points for which a network of collectors of 6,050 meters in total length is projected (all of them in Ø315 PVC) that run by gravity towards the WWTP, previously 3 spillways are executed for excess rainfall. Given the excavation depths and space limitations, it is necessary to carry out a 100 m long directional drilling in the main collector.

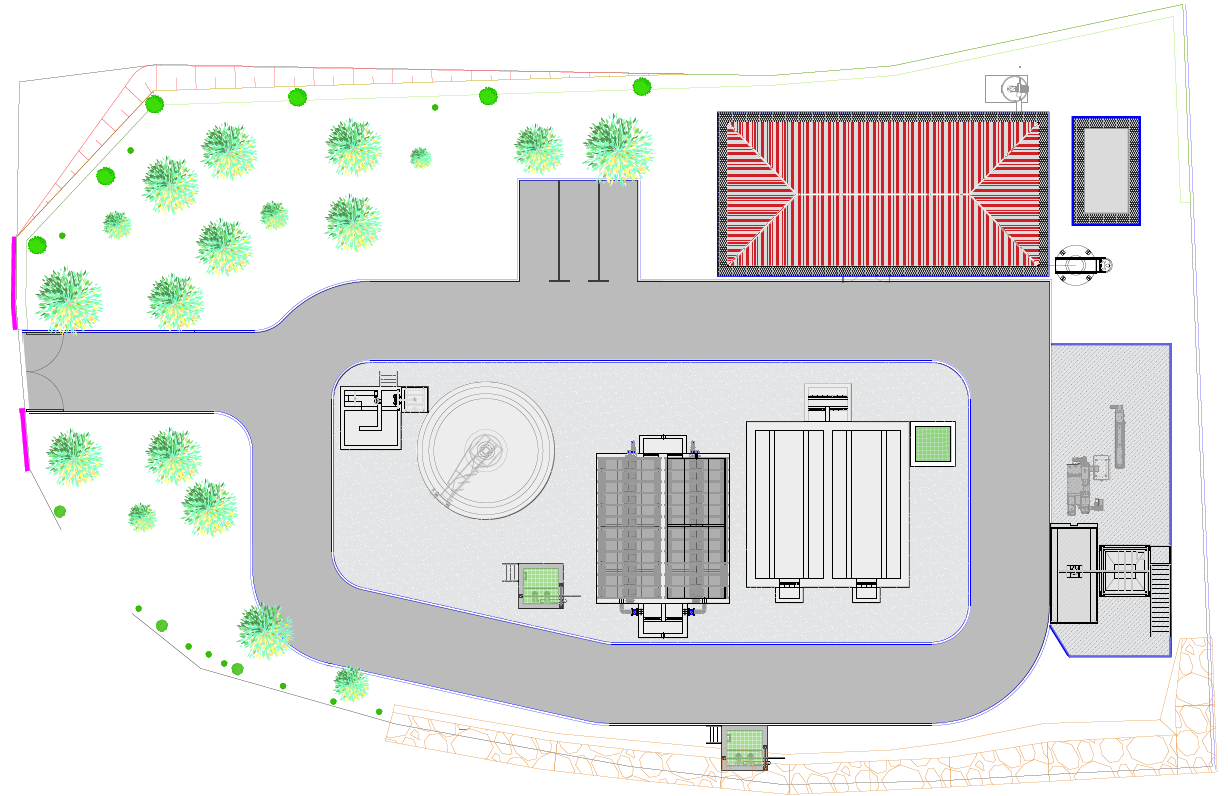

WWTP:

The WWTP water line is made up of the following elements: Coarse well, compact pretreatment, Imhoff tank, biodiscs, secondary decantation and chlorination labyrinth.

Regarding the sludge line, the sludge purged from the secondary clarifier is directed towards the recirculation chest from where it is pumped to the head of the Imhoff tank. For its part, the sludge purged from the Imhoff tank is pumped to the gravity thickener and from there to dehydration and drying.

Finally, the plant is provided with the necessary elements for its operation and maintenance (instrumentation and control, auxiliary services, electrical installations, etc.) as well as a control building.

The works consist of the execution of the AAVV and WWTP of the municipality of Iznatoraf (Jaén) which has a population of 1,250 inhabitants.

GROUPING OF SPILLS:

There are 6 discharge points for which a network of collectors of 6,050 meters in total length is projected (all of them in Ø315 PVC) that run by gravity towards the WWTP, previously 3 spillways are executed for excess rainfall. Given the excavation depths and space limitations, it is necessary to carry out a 100 m long directional drilling in the main collector.

WWTP:

The WWTP water line is made up of the following elements: Coarse well, compact pretreatment, Imhoff tank, biodiscs, secondary decantation and chlorination labyrinth.

Regarding the sludge line, the sludge purged from the secondary clarifier is directed towards the recirculation chest from where it is pumped to the head of the Imhoff tank. For its part, the sludge purged from the Imhoff tank is pumped to the gravity thickener and from there to dehydration and drying.

Finally, the plant is provided with the necessary elements for its operation and maintenance (instrumentation and control, auxiliary services, electrical installations, etc.) as well as a control building.